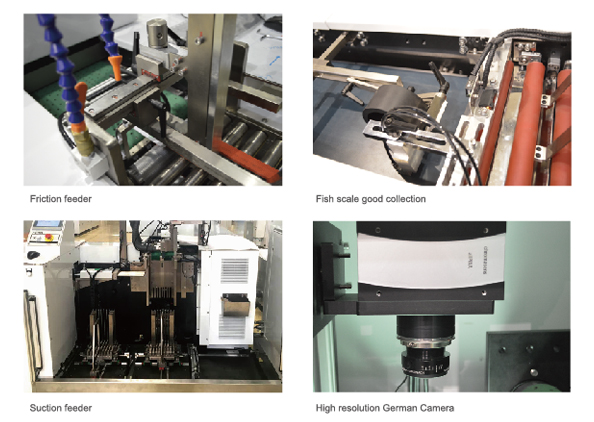

| FS-GECKO-200-A๏ผfriction feeder๏ผ | FS-GECKO-200-B๏ผsuction feeder๏ผ | |

| Maximum Inspection speed |

200m/min |

200m/min |

| Inspection size | 40mmโณ70mm~200mmโณ300mm | 30mmโณ50mm~200mmโณ200mm |

| Two-side inspection |

2 CCD cameras can be installed on both side (front and back) of machine, which can inspect mixed goods, color deviation, punching deviation and edge defect, normal printing defect, character defects, bar code defects and other defects. |

|

| Special configurations of mechanical platform |

Friction feeder: Smooth vibration with alloy feeder knife design | Suction feeder: Non-stop suction feeder design |

| Fully vacuum based transmission: No adjustment is required for transmission | ||

| Good Collection: accurate photo-electronic counting with high sensitivity with tidiness collection | ||

| Waste collection: Tidiness collection | ||

| Data is stored query |

With yipin, different batch number data query | |

| Defect statistics and management |

defect classification and statistics, printing statistical statement, efficient technique management | |

| Mechanical appearance size |

3650mm(L)x2000mm(W)x1800m(H) | 4600mm(L)x3200mm(W)x1800m(H) |

Tags