| Inspection speed | 250m/min | |

| Inspection Area | 90mm*90mm-500mm*420mm Products width 650mm/800mm width can choose suitable platform | |

| Paper Type | White/gray cardboards,METPET-Silver paper,Gold/laser paper | |

| Front Inspection Option | support installation 5 cameras at front | |

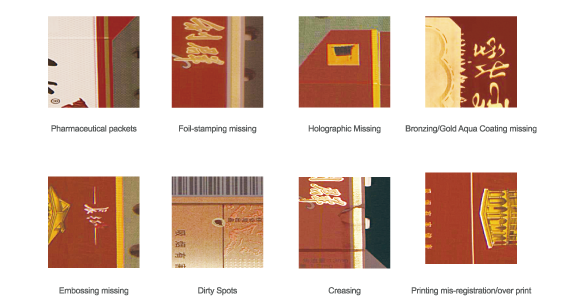

| Print quality detection: | Stripe,Ink spot,Color variation,Overprint,Misprinted | |

| Post print quality detection: | varnishing/lamination/Cast and Cure,Embossing/Die-cut/ | |

| Scratch,Foil Stamping/Holographic | ||

| Variable data module | QR Code and Verification code data check | |

| Position and appearance defect | ||

| High color accuracy module | Installation mutil channel German camera | |

| Sort products by different color with multi collection unit | ||

| Reverse Inspection | white/black CCD camera, Dirty, mosquito, appearance defects | |

| Automation Options | Multi collection unit | Color variation separate collection |

| Big defects separate collection | ||

| Variable data defects separate collection | ||

| Auto binging unit | Accurate counting,Complete the carton stacking, | |

| Convenient follow-up package | ||

| Mechanical appearance size | 18000mm(L)x4100mm(W)x2500mm(H) | |

Pharmaceutical

packets