"Intelligent Driving" Assistant for the Printing Industry--Focusight Offset Printing Online Eagle Eye Inspection System

2025 marks the "First Year of Intelligent Driving." In this era of technological empowerment, smart manufacturing has quietly integrated into our daily work. In printing enterprises, Focusight's "Offset Printing Online Eagle Eye Inspection System" is analogous to intelligent driving technology for vehicles, providing efficient and precise services for printing companies.

Real-time Defect Monitoring VS Real-time Driving Monitoring

Early Warning-guided Maintenance VS Navigation Driving Planning

Automatic Color Ink Adjustment VS Piloted Intelligent Driving

01.Safeguarding the Entire Printing Process

1. Domestic First: Pre-printing PDF Verification and Early Warning

Before the printing process starts, the Focusight Eagle Eye System acts as a rigorous "pre-auditor," automatically verifying the consistency between the actual printed product and the PDF original. Whether it’s layout errors, language discrepancies, pre-press mistakes, or plate defects, they can all be accurately identified. As the domestic pioneer in pre-printing PDF verification and early warning, Focusight saves enterprises the cost of purchasing separate offline verification equipment, effectively reducing costs and improving efficiency.

2. "Eagle Eye Intelligent Navigation" During Printing

Patented Air-blowing Flattening Technology: Adopts a unique air knife + air surface structure to solve the flattening problem of heavy-weight paper (over 350g). Equipped with a variable-frequency fan, it selects different frequencies based on paper weight to avoid energy waste and prevent water drying issues caused by excessive air temperature.

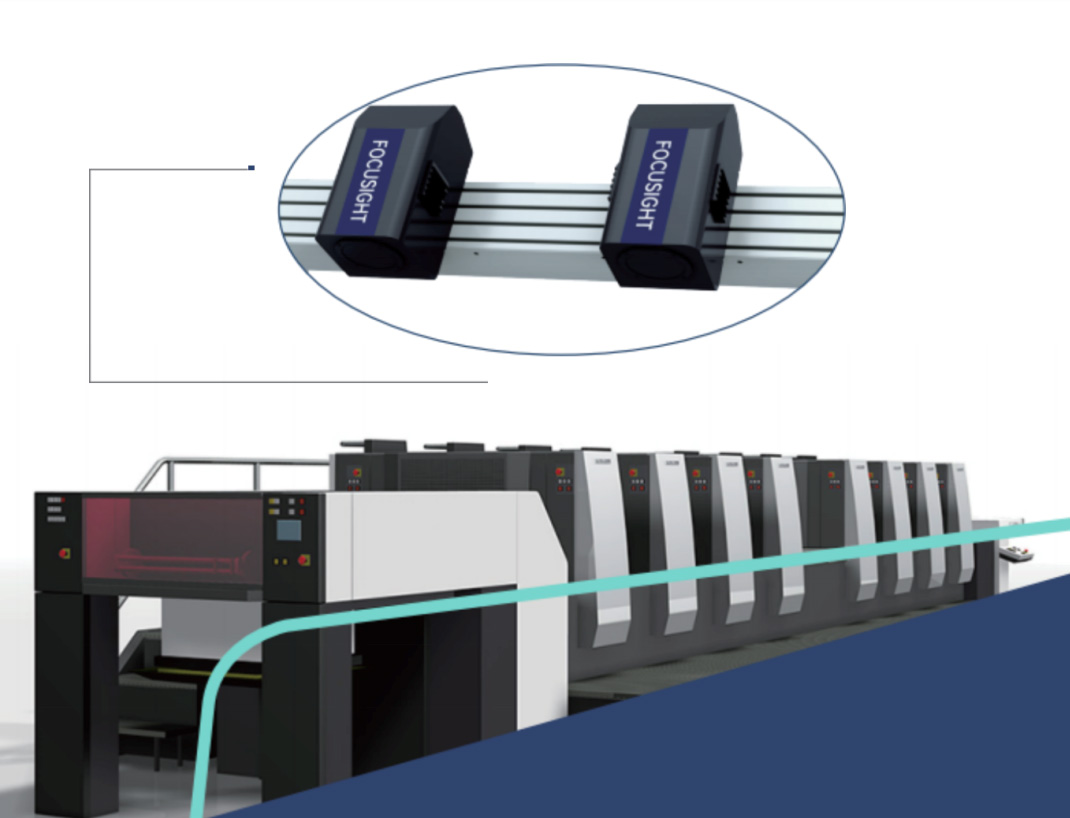

Dual 8K High-speed Color Cameras and High-brightness Water-cooled Light Source: Pioneers in solving the laser imaging problem for cigarette packaging, ensuring stable imaging and long service life. Even tiny defects and dirt can be accurately captured.

Defect Alarm and Marking System: Optional inkjet marking for defects and exclusive domestic reject bin installation. Real-time detection and marking of over ten common printing defects, including dirt, ink spots, misregistration, color difference, dry water, oil seepage, drag marks, ink pulling, plate fogging, ink skins, and substrate misalignment, with a maximum detection speed of 15,000 sheets/hour.

Continuous Waste Monitoring: Real-time display and alarm triggering for continuous waste. Customers can customize thresholds to automatically stop the feeder. Integrated AI intelligent recognition reduces false alarms and improves accuracy.

Color Measurement Module: Supports multi-region color difference measurement, real-time output of key data, high color difference detection precision, and results highly consistent with X-Rite professional equipment, ensuring precise color management.

Precise Production Output Control: AI filters defects to solve high false alarm issues; real-time statistics of qualified product quantities in the current printing batch help users track production progress and control output accurately.

3. "Quality Piloting Report Management" After Printing

After production, the system automatically prints pallet reports (red/yellow sheets), detailing major waste and continuous waste. An optional online reject bin can be added to real-time remove major and continuous waste, supporting direct shipment after die-cutting or connection to folding-gluing processes. Multiple reviews ensure strict control, preventing major defects from reaching end customers.

Full MES System Integration: Achieves comprehensive connectivity, enabling deeper client-side management.

Data Transmission and Fault Analysis: Through piloting reports, data sharing between online Eagle Eye detection and offline inspection machines delivers in-depth management value.

Specialized Solutions:

For cigarette packaging and wine box products with light column paper, the unique MateLize imaging light source effectively filters surface light columns of laser materials, reducing false alarms and improving detection accuracy.

For pharmaceutical packaging, in addition to regular defects, it detects empty drug regulatory codes and severe misalignment, triggering separate alarms and recording them in pallet reports to achieve full-process inspection of pharmaceutical packaging.

02.Our Value

For Quality Managers: More accurate traceability of customer complaints, significantly reducing complaint frequency; clear basis for rewards and penalties ensures fairness; clear direction for production quality improvement.

For Press Operators: Reduces pre-startup preparation time; real-time precise detection enables confident speed increases; timely avoidance of major/continuous waste leads to fewer fines.

For Production Managers: Ensures on-time delivery of orders; manages continuous waste in front-end processes; helps optimize savings in ink, paper, consumables, and labor costs.

For Enterprise Leaders: Reduces waste, cuts costs, enhances reputation, increases orders, and supports sustainable business development.

We provide fast and efficient installation services, ensuring equipment operation within 48 hours, along with a one-week training program to standardize processes.

The Focusight Offset Printing Online Eagle Eye System has hundreds of successful mapping and construction cases, perfectly adapting to top printing presses such as Heidelberg, KBA, Komori, and Roland, with the model library continuously expanding.

For more details, please consult sales engineers in each region.